TraffiGlove TG3140 Morphic Cut Level B Safety Gloves

Ideal for general handling tasks in assembly and maintenance, the TraffiGlove TG3140 Morphic Cut Level 3 Gloves feature a dexterous, highly sensitive MicroDex nitrile coating. Additionally, they offer impressive mechanical protection against cuts, abrasions and scrapes.

Purchase Quantity

The TraffiGlove TG3140 Morphic Cut Level 3 Safety Gloves are supplied as a pair of gloves.

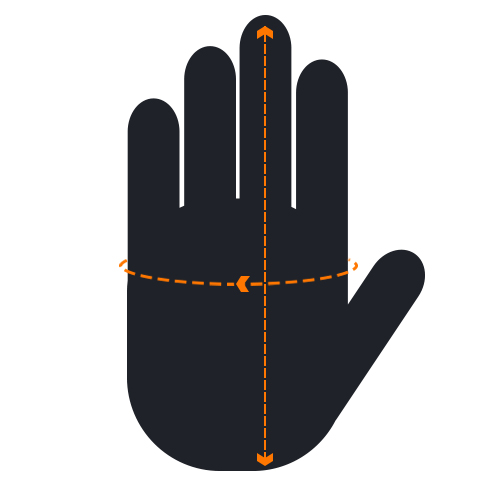

Sizing Information

To find the right size for you, measure the length and circumference of your hand as demonstrated in the diagram and match your results to the sizing table provided.

| Size | Circumference (mm) | Length (mm) |

| Size 6 | 152mm | 160mm |

| Size 7 | 178mm | 171mm |

| Size 8 | 203mm | 182mm |

| Size 9 | 229mm | 192mm |

| Size 10 | 254mm | 204mm |

Read our guide to sizing for more information about finding your perfect size.

How Do the TraffiGlove TG3140 Gloves Protect Your Hands?

These gloves can protect users from scratches, scrapes and cuts in medium risk environments. Fitted with a resilient liner made from nylon and high performance polyethylene, they attain the highest possible EN 388 standards for abrasion and tear resistance, as well as good levels of puncture and cut resistance. Meanwhile, their MicroDex nitrile coating adds grip and dexterity for safer tool handling.

Performance Ratings

EN 388 (Protection Against Mechanical Risks)

| Test | Result |

| Abrasion | Level 4 |

| Cut | N/A |

| Tear | Level 4 |

| Puncture | Level 3 |

| Blade Cut | Level B |

Read our guide to EN 388 for more information.

Key Features and Benefits

- Gloves offer protection against dirt, scratches and scrapes

- MicroDex nitrile coating enhances grip and dexterity

- Coating enables tactile sensitivity for precision tasks

- Snug fit allows for a greater range of movement

- Nylon and HPPE liner is strong yet comfortable

- Nitrile coating improves grip in wet or oily conditions

Who Can Use the TG3140 Gloves?

Well-suited to assembly or maintenance tasks, these gloves offer high levels of dexterity, sensitivity and grip in dry, wet or oily conditions. Their properties make them suitable for a range of other industries and sectors, including:

Additional Documentation